| The CPW 26” HFI mill (High Frequency Induction welding) is currently one of the largest-diameter HFI Pipe plant in the world using the cage roll forming method. It is considered to be the most effective forming technique for higher strength and larger diameters line pipe products.The annual production capacity is 400,000 tons, outside diameter range from 8 5/8’’ to 26’’, steel grade up to X80 and wall thickness range from 4.78mm to 25.4 mm. The ERW/HFI mill also manufactures hollow structural sections of large dimensions (from 180x180 to 500x500 and 600x400 mm), which are widely used in metal constructions. The mill was manufactured by the German company SMS-MEER. |

|

|

Production Range

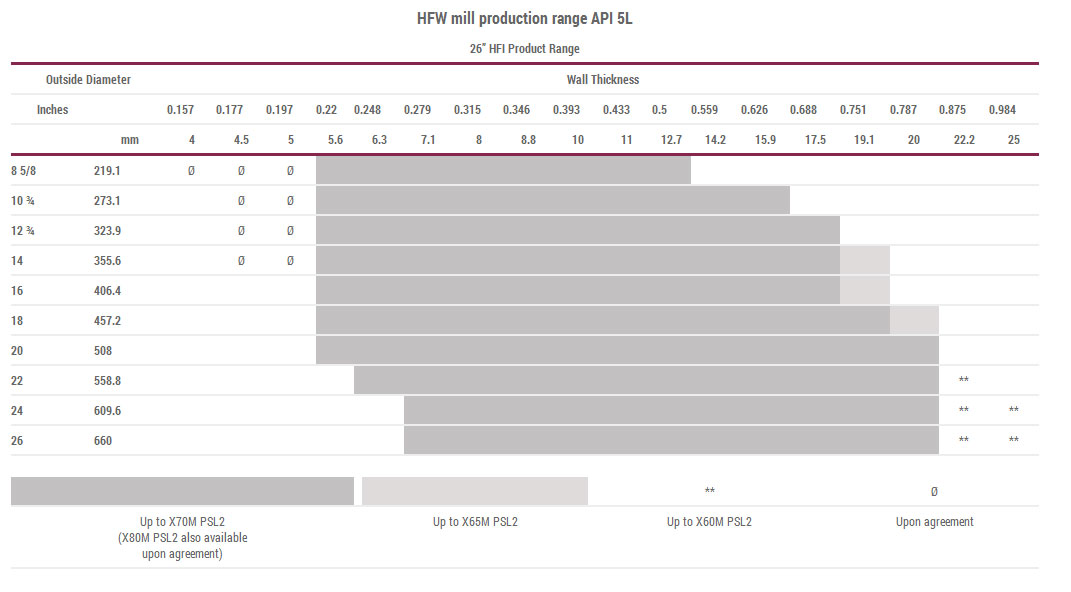

1. API 5L

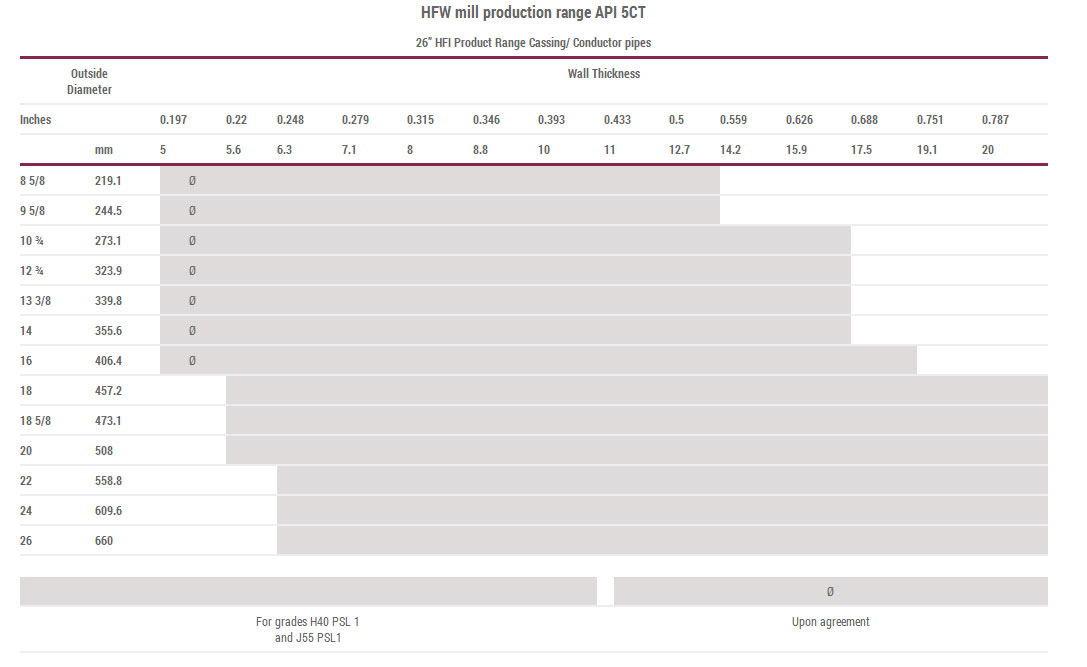

2. API 5CT

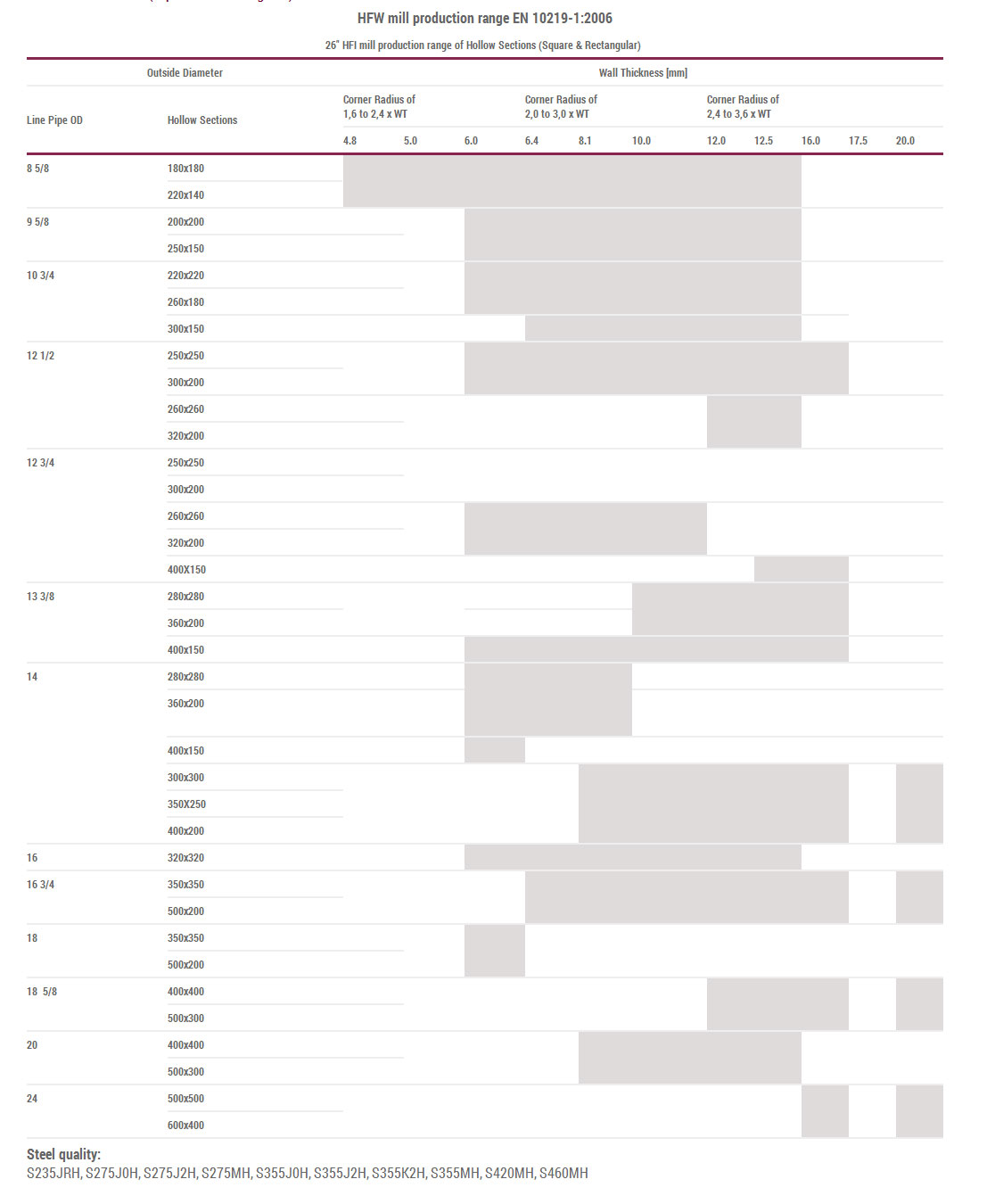

3. Hollow Sections (Square & Rectangular)

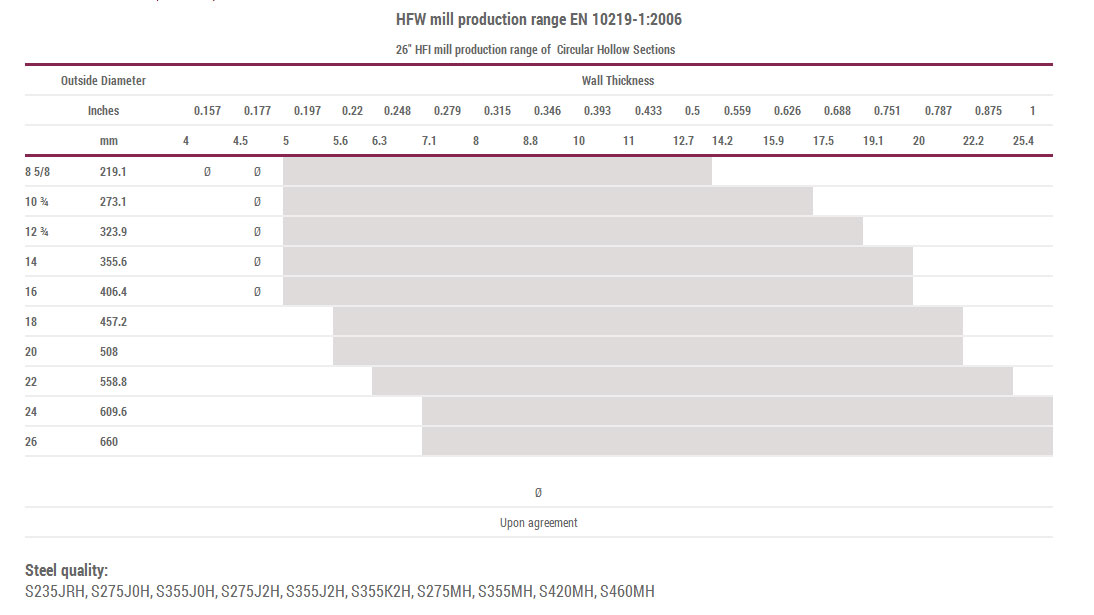

4. Hollow Section (Circular)

Production Standards & Steel Qualities

- Line Pipe

- API 5L & ISO 3183

- PSL1 pipe/steel grades: A (L210), B (L245), X42 (L290), X46 (L320), X52 (L360), X56 (L390), X60 (L415), X65 (L450), X70 (L485)

- PSL2 pipe/steel grades: A (L210M), B (L245M), X42 (L290M), X46 (L320M), X52 (L360M), X56 (L390M), X60 (L415M), X65 (L450M), X70 (L485M), X80 (L555M)

- EN 10208-2

- PSL2 steel grades: L245MB, L290MB, L320MB, L360MB, L390MB, L415MB, L450MB, L485MB, L555MB

- Casing

- API 5CT

- Group 1, H40/PSL1 & J55 PSL1

- EN 10208-2

- PSL2 steel grades: L245MB, L290MB, L320MB, L360MB, L390MB, L415MB, L450MB, L485MB, L555MB

- Cold formed welded structural hollow sections of non-alloy steels

- EN 10219-1 & 2

- S235(JRH), S275(J0H, J2H, MH), S355(J0H, J2H, K2H, MH), S420(MH), S460(MLH)

Sizes

Length: 8.00 - 24.4m

NDT standards

- EN 10208-2: Annex C

- API 5L: Annex E, Annex K

- API 5CT: § 10.15.10, §10.15.13, Table E.44

- EN 10219-1: § 9.4.2 a)

Heat Treatment

For whole product range weld seam annealed.

Finishing Operations

Plain-End, Square Cut or bevelled.

Surface Condition

- Black self-colored / uncoated

- Mill protective coating (varnish) on outside surface

- Three Layer Extruded Polyethylene – Polypropylene coating (plus rough coating)

- Fusion Bond Epoxy Single – Dual Layer coating

- Liquid Epoxy coating

Mill Test Certificates

Certification according to EN 10204 2.1; 2.2; 3.1; 3.2

Quality Certificates

- Quality Assurance System Certificate:

- ISO 9001, API Specification Q1, DIN EN ISO 3834-2, EN ISO 3183, EN 10219-1

- Production Approval Certificates:

- API 5L, API 5CT, Germanischer Lloyd AD 2000 Merkblatt HP0, EN 764-5, Germanischer Lloyd AD 2000 Merkblatt W0, ABS_NRF-026

- Laboratory Accreditation Certificate:

- ISO / IEC 17025, Hellenic Accreditation system (ESYD)

Test Performed

- Hydrostatic Test

- Visual and Dimensional Inspection

- Laboratory Tests:

- Chemical Analysis

- Tensile test

- Charpy V-Notch impact test

- Guided Bend test

- Drop Weight Tear (DWT) test

- Metallographic Examination

- Hardness test

- Reverse Bend test

- Flattening test

- Hydrogen Induced Cracking (HIC) test

- Sulfide Stress Corrosion Cracking (SSCC) test

- Crack Tip Opening Displacement (CTOD) test

- Strain and Ageing Tests

- Non Destructive Inspection: Ultrasonic inspection (pipe body & weld), Magnetic Particle inspection (weld)