Helical Submerged Arc Welded (SAWH) pipemill has a capacity of 375.000Tn/y and is producing steel pipes with external diameters ranging from 24’’ to 100’’, wall thickness up to 25,4mm, pipe lengths up to 18m and steel grades up to X80 using the two step manufacturing process. The “Two-step” process consists of two distinct operations: pipe forming/continuous tack welding and double submerged arc welding. The mill was manufactured by the German company SMS-MEER.

The “Two-step” process offers major benefits over alternative technologies primarily due to their advanced technical characteristics, namely:

- Flexibility

- Low installation cost

- Lower production cost

- Higher productivity

- Superior dimensional characteristics and weld quality

|

|

|

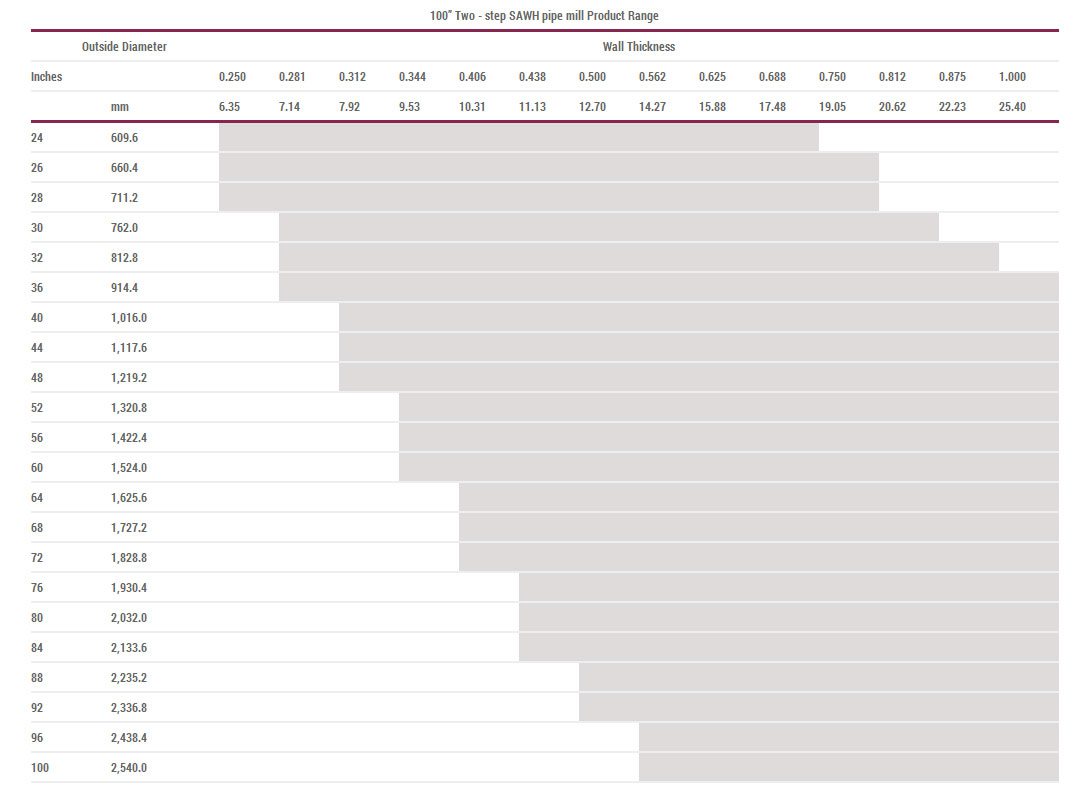

Production Range

or any other itermediate O.D. and W.T. size required by the customer

STEEL GRADe: API 5L/ ISO 3183 Grade BM/L245M up to X80M/L555M (Sour service up to X65M/ L450MS)

Steel Qualities

Steel Grade: API 5L / ISO 3183 Grade BM / L245M up to X80M / L555M (Sour Service up to X70MS / L485MS)

Production Standards

- API 5L

- ISO 3183 / AnnexM

- TS-C4GAS – PIP0

- DNV-OS-F101

- EN 10219-1,2

- AWWA C200

- DIN 1626

- ASTM A252

NDT Standards

- ISO 10893 - 6-11

- API Annex E, Annex K

Quality Certificates

- Quality Management System Certificates: API Q1 (Q1-0115), ISO 9001 (API QR 0194), EN 746-5 (GL DZ 134 HH)

- Product Certificates: API 5L (5L-0396), UDT Poland (M-238), AD 2000-Merkblatt HP0 (GL WF 1210247-1 HH), AD 2000-Merkblatt W0 (GL WZ2537 HH), ISO 3834-2 (GL 1210247 HH), EN 10219-1,2 (DNV 1162-CPR-0471), ISO 3183 (ZETOM Poland 80/14 & ABS Mexico 14-066-RX)

Sizes

Outside diameter: 24’’ - 100’’, 609.6mm - 2540.0mm

Wall thickness: 0.25’’ - 1’’, 6.35mm - 25.40mm

Length: 8.00 - 24.4m

Mill Test Certificates

Acc. To EN 10204 2.1, 2.2, 3.1, 3.2

Finishing Οperation

Plain end, square cut or beveled.